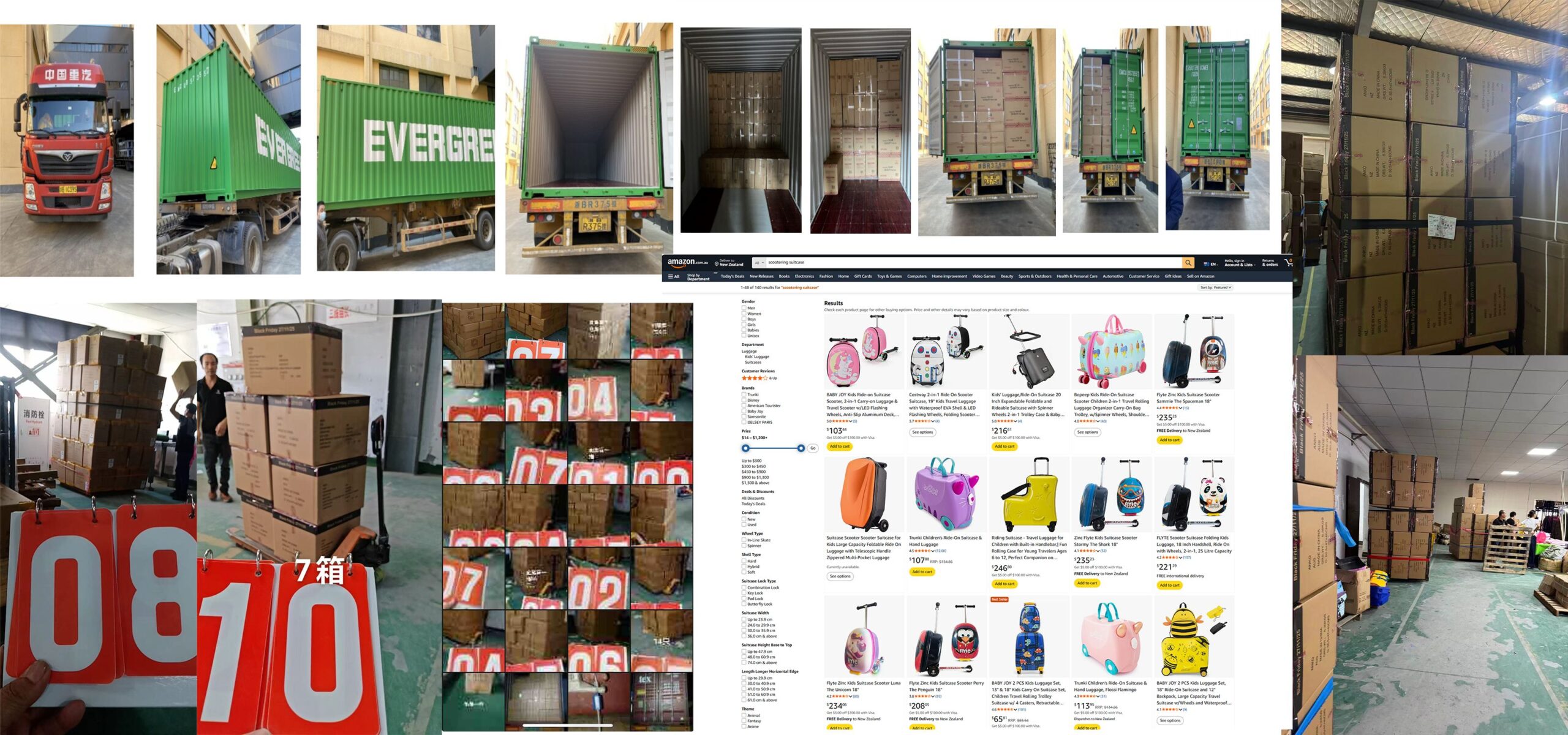

A lot of customers may think warehouse managements for factories, cannot be difficult,, but in increasingly E-COM driving business, it requires more precise managements of SKU, and more segmented wareho8uise and loading approached. Previously if you doing largr quantitiees, less SKUs, you don’t need warehouse people able to read simple english, but now, with E-COM, a containers are loading far more SKU, each SKU less quantities, because they are heading straight to FBA / AMAZON warehouses. Therefore, we need to plan everything way ahead, from container loading into warehousing managementx. they are more sstrict, about precise managemetn of warehousess As well.

For example, if we doing TARGET / WALMART / ALDI orders, they are big quantities, with less SKU, therefore when production finish , they just load into part of the warehouses. But w E-COM, because each SKU, will be shipped by foretasted weekly sales, so even if it still 100 pcs for example, we will warehouse them into diff pallets, this way, when comes to loading, it will be shipped with other SKUs. Furthermore, it also requires more timely movements, as all QR stickers and bar codes will need to be out within 1 week of coming into warehouses, otherwise, most of US / EU parts takes longer than 20 days from China, into their designated ports, and by the time finish customization, it won’t be able to scanned anymore due to platform’s time requirements on bar-cods.

Therefore, we, as a luggage factory, we are actually required to have much more precise warehouse management and services provided to making sure there is max we can do, without them having to be charged a fortune to have this services provided locallyif Our refined dispatch management integrates robust systems for accuracy and reliability, turning logistical challenges into seamless advantages for clients. Stay competitive with Zhongdi!

In response to the increasingly strict-shipping rules on Amazon, our operations are transitioning as we implement upgrades to our factory warehouse.

With e-commerce giants like Amazon, and the platforms giving more traffic to links w FBA / its internal warehouses, we have more clients doing MORE SKU, LESS QUANTITIES to ship each containers, so we increasingly setting stricter standards.Previously our warehouses, are more customized to do more large quantities, less SKU, so may be can use more “less educated” but “faster in loading containers” now, the focus are making sure “the housewares can also read EN, and scan QR codes relentless for each carton / pallets we load, so if there is any issues, they are SMART ENOUGH to catch ,and making sure there is seperatations when coming to loading. We’re upgrading processes, tech, and training to ensure flawless deliveries.

#SupplyChain #Logistics #Container Loading #Walmart #E-commerce #AmazonFBA #Shipping #ProcessImprovement #Amazon